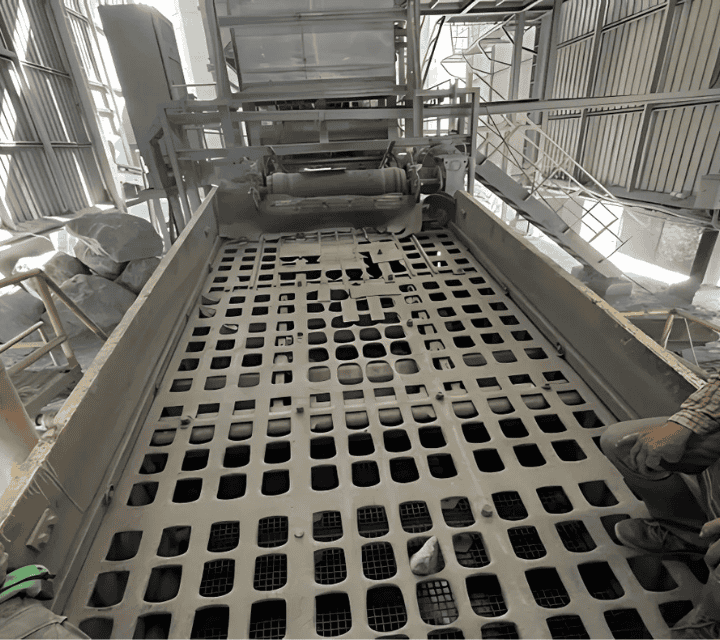

Hardox 450 provides significant advantages in rock sorting screen applications. Its exceptional wear and impact resistance, combined with enhanced toughness and corrosion resistance, contribute to reduced downtime and extended equipment lifespan. This results in lower maintenance costs over time. While it may have a higher initial cost, the long-term savings and performance improvements make it a valuable investment for industries that handle abrasive materials. The durability and strength of Hardox 450 help ensure that equipment performs efficiently, even under challenging conditions.

OUR PROJECT

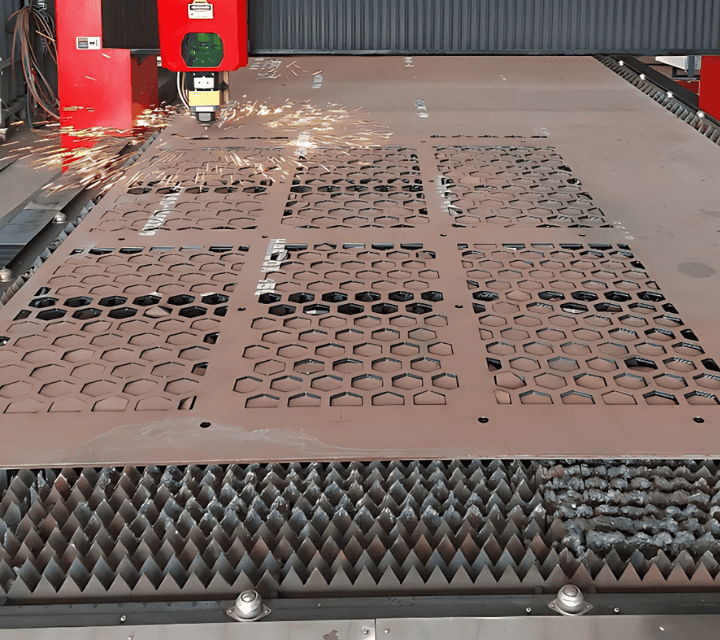

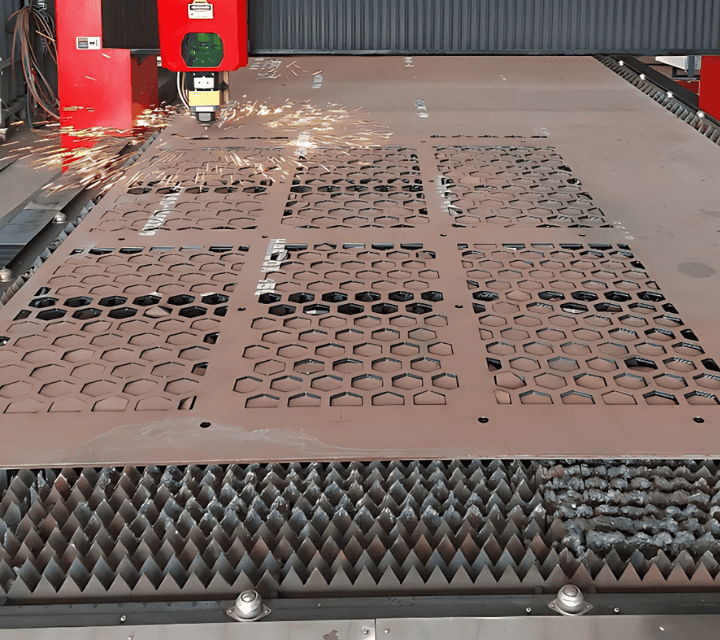

Enhancing Rock Sorting Screen Performance with Hardox 450

Description

In industries such as mining, aggregates, and recycling, rock sorting screens are crucial for separating and processing materials. These screens are exposed to extreme wear and tear due to their constant interaction with abrasive materials like rocks and minerals. As a result, their performance can degrade over time, leading to downtime, costly repairs, and decreased efficiency.

Environmental challenges faced by rock sorting screens include:

- Abrasive Wear: Constant rubbing of hard materials leads to thinning and reduced efficiency.

- Impact Loads: Large, heavy rocks cause localized wear and deformation.

- Corrosion: Exposure to moisture and chemicals weakens the screen’s structure.

- Fatigue: Continuous vibrations can cause cracks and breakages in steel materials.