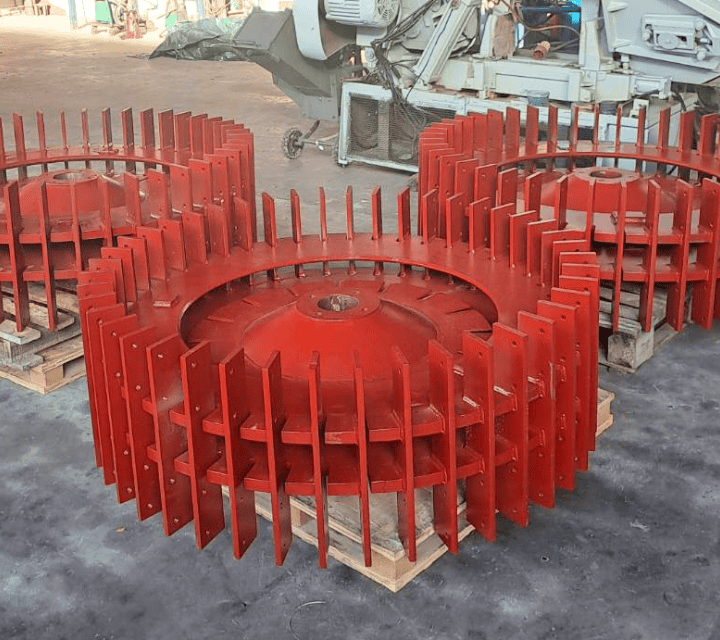

OUR PROJECT

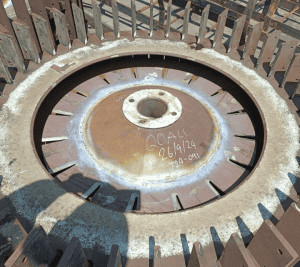

Upgrade the impeller mill’s plate with Hardox 450

Description

An impeller mill is a high-efficiency grinding and chipping machine used in the timber industry for processing wood into fine particles or uniform chips. It plays a important role in an industry such as Particle Board production, pulp production and wood waste recycling by utilizing centrifugal force and high-speed impact.

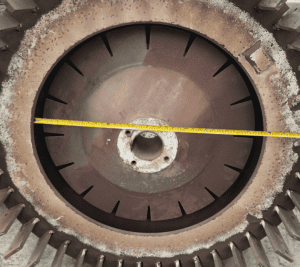

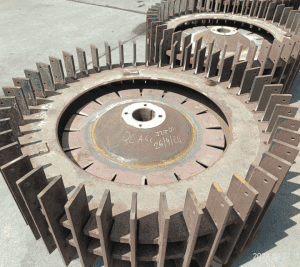

One of the common challenges of the impeller plate is, it will easily wear or abrasion caused by continuous wood chipping and grinding, then the results reduce the impeller’s lifespan. Normal tensile carbon steels quickly wear out, then it’s affecting mill performance.

New Solution

Mild steel

New Solution

Hardox 450 is a great choice for impeller mill, it’s offer significant benefits in terms of durability, efficiency, and maintenance costs. Hardox 450 is a high-strength, wear-resistant steel that enhances the performance of impeller mills in the timber industry.

Here’s why:

- Optimal Hardness: At 450 HBW, it resists abrasion from wood particles effectively.

- Impact Resistance: It’s tough enough to absorb impacts without cracking, ideal for milling operations.

- Longer Service Life: Reduces wear and tear, minimizing replacements and downtime.

- Cost-Effective: Though pricier upfront, its durability reduces long-term maintenance costs.

- Versatile: Handles both abrasion and impact in various milling conditions.

- Proven Performance: Widely used in industries with heavy wear, making it a reliable choice.

Hardox 450 offers an excellent balance of wear and impact resistance, extending the life of your mill’s components.