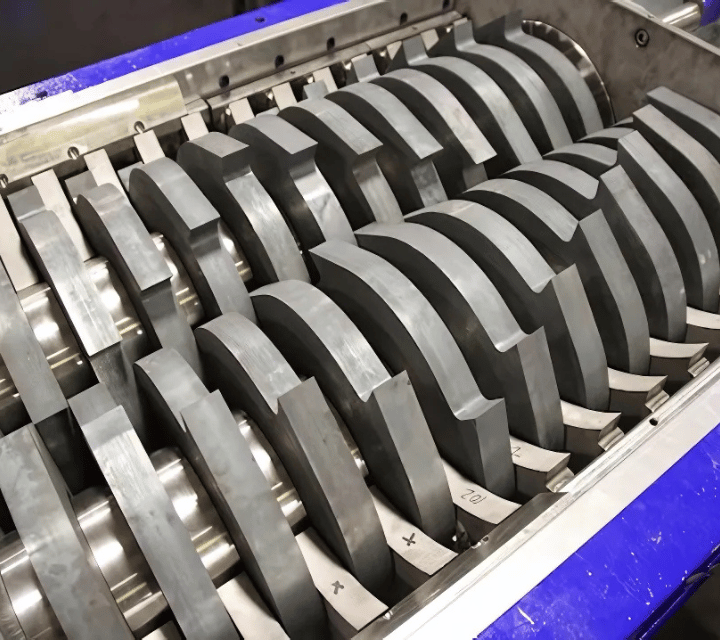

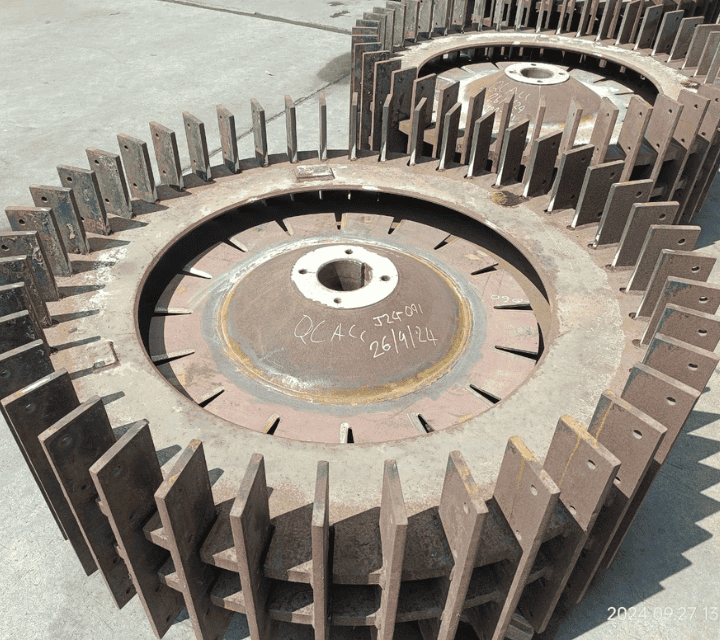

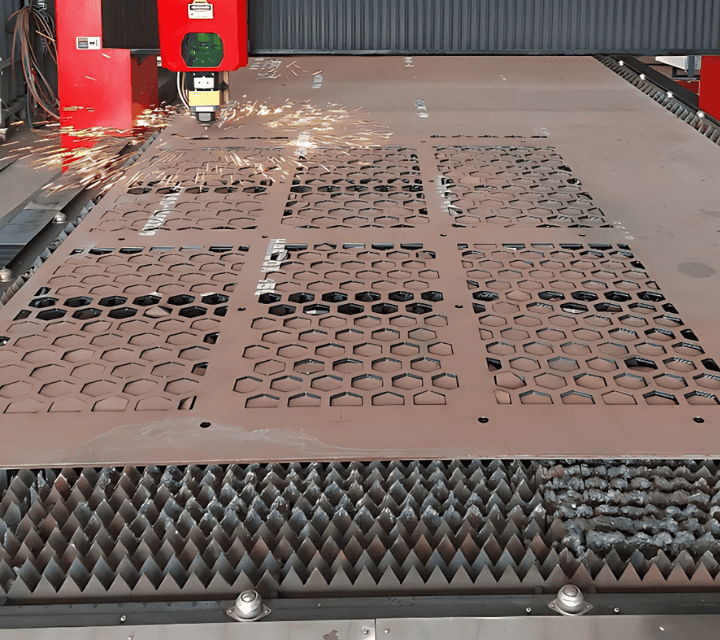

Hardox Solutions for Durable Waste Disposal in Extreme Conditions

Hardox 450 and other high-strength, abrasion-resistant steels are highly suitable for wear parts in waste disposal equipment. These materials offer excellent resistance to corrosion and weathering, making them more reliable and durable over time, even in harsh environments.